IiNkcazo zeeMveliso

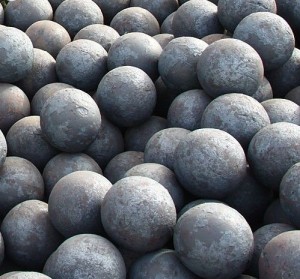

intsimbi ebunjiweyoibhola yokusilas iindawo zokusila

Intsimi yezicelo ze-Cast Chrome Alloy Grinding Steel Balls, ngokufutshane iiBhola zentsimbi zeCast, zinokufumaneka kwiSamente.

Izityalo, iMigodi, izikhululo zoMbane, aMashishini eMichiza, iMill yokuSila, iBall Mill kunye neCoal Mill.

Izityalo, iMigodi, izikhululo zoMbane, aMashishini eMichiza, iMill yokuSila, iBall Mill kunye neCoal Mill.

Sineentlobo ezi-4 eziphambili zezi bhola: I-chrome ephantsi, i-chrome ephakathi, i-chrome ephezulu kunye ne-chrome ephezulu.Ubukhulu bukuluhlu lwe-10mm - 150mm.

Iimbonakalo:

I-1. Ibhola yentsimbi ekhandiweyo inobunzima obuphezulu: ubunzima bomhlaba ukuya kwi-58-65HRC, ubunzima bevolumu ye-57-64HRC

2. Ukuqina kwempembelelo ephezulu: ukuqina kwempembelelo ngaphezu kwe-12J / cm2.

3. izinga eliphukileyo liphantsi: izinga langempela eliphukileyo alikho ngaphezu kwe-0.5%.

4. ilahleko yembumbulu yokusila ibhola kwinqanaba elijikelezayo liphantsi.

5. Uvavanyo lokuwisa kwi-8m yovavanyo oluphezulu ngaphezulu kwamaxesha angama-20,000.

I-1. Ibhola yentsimbi ekhandiweyo inobunzima obuphezulu: ubunzima bomhlaba ukuya kwi-58-65HRC, ubunzima bevolumu ye-57-64HRC

2. Ukuqina kwempembelelo ephezulu: ukuqina kwempembelelo ngaphezu kwe-12J / cm2.

3. izinga eliphukileyo liphantsi: izinga langempela eliphukileyo alikho ngaphezu kwe-0.5%.

4. ilahleko yembumbulu yokusila ibhola kwinqanaba elijikelezayo liphantsi.

5. Uvavanyo lokuwisa kwi-8m yovavanyo oluphezulu ngaphezulu kwamaxesha angama-20,000.

Inkcazo

Iimpawu eziphambili zeCast Chrome Alloy Grinding Steel Balls:

| Iiparamitha | I-Chrome ephantsi | IChrome ephakathi | IChrome ephezulu | IChrome ephezulu |

| Cr % | 0.8 - 3.5 | 4 – 9 | 10 – 18 | 22 – 25 |

| C% | 2.2 – 3.5 | 2 – 3.3 | 1.6 – 3.3 | 2.0 – 3.3 |

| Si % | 1.2 ubuninzi | 1.2 ubuninzi | 1.0 ubuninzi | 1.0 ubuninzi |

| Mn% | 1.5 ubuninzi | 1.8 ubuninzi | 2.5 ubuninzi | 2.5 ubuninzi |

| Mo % | 1.0 ubuninzi | 1.5 ubuninzi | 1.0 ubuninzi | 2.0 ubuninzi |

| Cu % | 0.5 ubuninzi | 1.0 ubuninzi | 1.5 ubuninzi | 1.5 ubuninzi |

| P% | 0.15 ubuninzi | 0.15 ubuninzi | 0.10 ubuninzi | 0.10 ubuninzi |

| S % | 0.15 ubuninzi | 0.15 ubuninzi | 0.10 ubuninzi | 0.10 ubuninzi |

| Ubume beMetallographic | Carbide + Pearlite | Carbide + Pearlite | Carbide + Martensite | Carbide + Martensite |

| Ukuqina (HRC) | 45 okanye ngaphezulu | 50 okanye ngaphezulu | 58 okanye ngaphezulu | 60 okanye ngaphezulu |

| Amaxesha ebhola ewayo | 8000 okanye ngaphezulu | 12000 okanye ngaphezulu | 15000 okanye ngaphezulu | 22000 okanye ngaphezulu |

Iidayamitha zebhola ezifumanekayo:

| I-Nominal Diameter kwi-mm | Ubunzima nge kg ngebhola nganye ngokomndilili | Inani leeBhola ngetoni nganye kumndilili |

| 10 | 0.135 | 74073 |

| 12 | 0.0181 | 55248 |

| 15 | 0.0242 | 41322 |

| 20 | 0.0322 | 31056 |

| 25 | 0.063 | 15873 |

| 30 | 0.11 | 9091 |

| 40 | 0.257 | 3891 |

| 50 | 0.5 | 2000 |

| 60 | 0.867 | 1153 |

| 70 | 1.37 | 729 |

| 80 | 2.05 | 487 |

| 90 | 2.90 | 345 |

| 100 | 4.00 | 250 |

| 110 | 5.30 | 188 |

| 120 | 6.80 | 147 |

| 125 | 7.75 | 129 |

| 130 | 8.74 | 114 |

-

Iintengiso ezilungileyo zokuSila iMedia yentsimbi yeBhola yeBhola yeMila

-

I-Precision G25 yokuSila iMedia

-

Umgangatho oPhezulu wexabiso eliphantsi 20-150mm Steel Forged Ca...

-

Ibhola yeTungsten Carbide

-

Ukuphosa intsimbi yentsimbi ePhantsi yeChrome yeSigrindi...

-

Iibhola zeTungsten Carbide zokuSila iMedia