Tšebeliso ea indasteri:

Lisebelisoa tsa ho haha samente

Merafo ea tšepe

Mashala peista litsi tse futhumatsang mocheso

Boenjiniere ba lik'hemik'hale

Ho roala ka ceramic

Indasteri ea leseli

Lisebelisoa tsa makenete

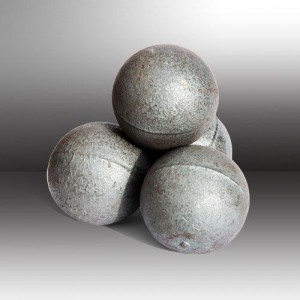

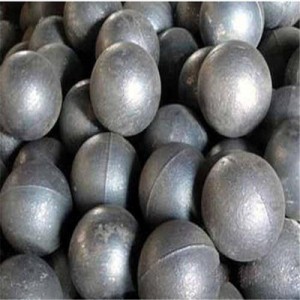

Ho lahla bolo e silang, libolo tsa leloala, bolo ea media e silang.

Ka boima bo phahameng le ho se mamelle,

Chrome e ka fetoloa joalo ka tlhoko ea bareki,

Boholo bo ka ba 8mm-150mm,

boima ho tloha 58 ~ 68,

Haeba ho hlokahala boima bo khethehileng ba mophato kapa tse ling, re ka khona ho fetola le ho tsamaisana le tlhoko ea hau

TS'ELISO TS'OANELO

1.Tlhahiso e entsoeng ka mokhoa o ikhethileng oa lisebelisoa tse tala→2.tlhahlobo ea thepa e tala→3.beha thepa e tala ka setofong' me u e futhumatse ka mocheso o itseng→4.ho forging/hot rolling process→5.Isothermal process→6.Ho tima→7. pholiso ea tlhaho→8.Ho futhumatsa →9.Tlhahlobo e felletseng ea sehlahisoa→10.Ho paka le ho boloka