The key to our success is “Good Solution Top quality, Reasonable Value and Efficient Service” for OEM Manufacturer China 100% Virgin PTFE Tube / Pipe Reach E. U. and U. S Market Standard, As a leading manufacture and exporter, we enjoy a good reputation in the international markets, especially in America and Europe, because of our top quality and reasonable prices.

The key to our success is “Good Solution Top quality, Reasonable Value and Efficient Service” for China Teflon Tube, Teflon Pipe, We always stick to the tenet of “sincerity, high quality, high efficiency, innovation”. With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

- Place of Origin:

-

Hebei, China

- Brand Name:

-

TM

- Model Number:

-

1″-60″

- Product name:

-

ptfe lined pipe

- Thickness:

-

1-10mm

- Length:

-

as customized

- Connect:

-

flange

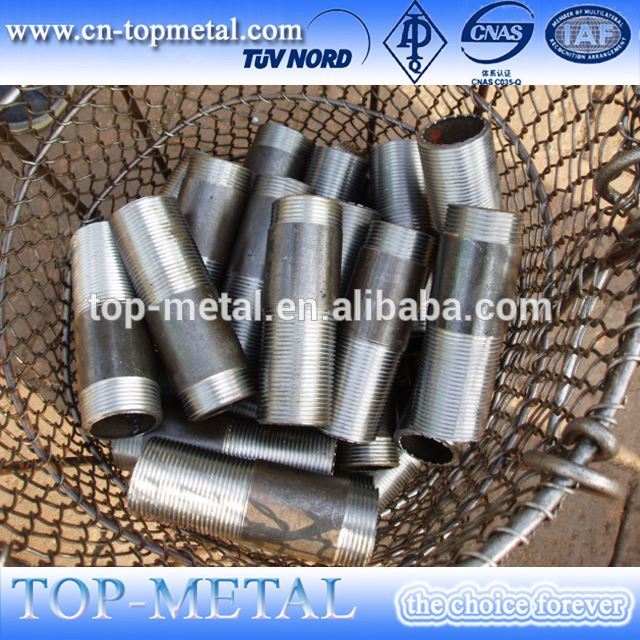

Nominal diameter: DN25~DN300,1″~12″

Length: ≤6000mm (size≤DN150) ≤4000mm (size>DN150)

Temperature range: -29°C~180°C

Applicable medium:

Able to transport any concentration of acid, alkali, organic solvents, strong oxidant, toxic and volatile, flammable chemicals.

Specification Instruction:

Kaxite manufactures PTFE lined pipe and fittings by compression molding, isostatic molding, injection molding, transfer molding,

hot rotomolding, ram/paste extrusion, 3D rotational molding etc. Characters as below:

• Working temperature is high at the range of -29°C-200°C; except the molten alkali metals, element fluorine and aromatic

hydrocarbon, lined products can be used in any chemical medium.

• Vacuum resistance. In the range of -29°C-150°C, it is applicable for vacuum condition. In chemical production, the vacuum

condition occurs due to cooling, longitudinal emissions, or medium backflow.

• High-pressure resistance. Within temperature working condition, it can sustain the working pressure of 3.0 MPa.

• Resistance to penetration. Adapt the high-quality PTFE, to make it of high density and enough thickness after advanced lining

processing, make it excellent antiosmosis.

• PTFE advanced lining molding process achieved the status of syn chronous hot expansion or cold shrinkage for steel components

and fluorine plastic.

• Kaxite us adopts the standard size according to HG, GB, DIN, ANSI, and JIS etc., which improves interchangeability, to provide

convenience for installation.

Data sheet

Specific Gravity: 2.14-2.19g/cm3 as per ASTM D 792 test standard.

Tensile Rate: 20.7Mpa minimum as per ASTM D 638 test standard.

Elongation Rate: 250% minimum as per ASTM D 638 test standard.

Manufacture Standard: ASTM D 4895. Operating in vacuum condition within 150°C