Product Detail

Product Tags

Quick Details

- Standard:API, ASTM

- Standard2:API 5L, ASTM A53-2007

- Grade Group:A53-A369

- Grade:A106(B,C), A53(A,B)

- Thickness:1.65 – 25.4 mm

- Section Shape:Round

- Outer Diameter(Round):0.5 – 48 inch

- Secondary Or Not:Non-secondary

- Technique:Hot Rolled

- Certification:API

- Surface Treatment:As customer’s requirement

- Special Pipe:API Pipe

- Alloy Or Not:Non-alloy

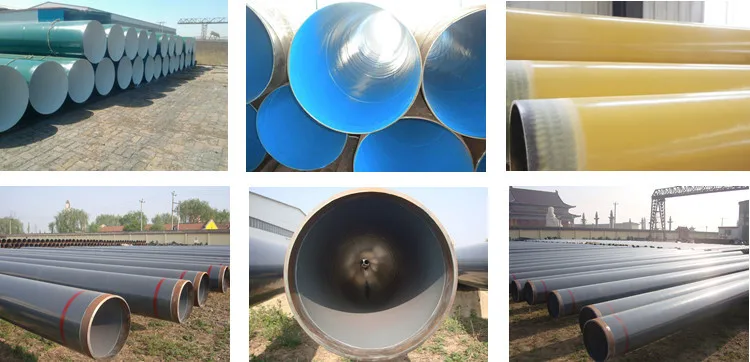

- Name:Insulation Pipe & Anti-corrosion 3PE Coated API 5L Pipes For Water

- Type:Water Steel Pipe

-

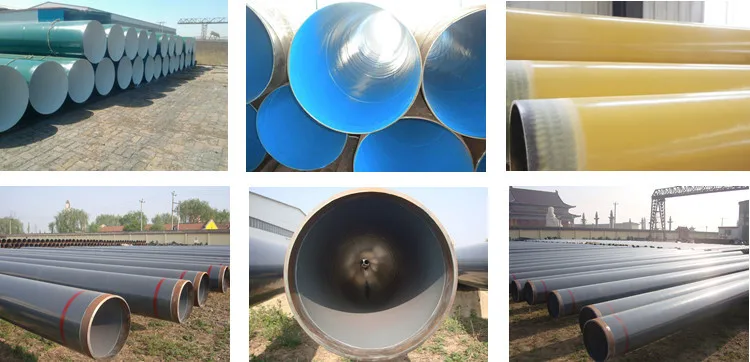

Insulation Pipe & Anti-corrosion 3PE Coated API 5L Pipes For Water

Basic Information of Coated Steel Pipe

| Standard |

API 5L-2009 / ISO 3183-2007 |

| Grade

( Material)

|

PSL-1 |

Gr.B/X42/X46/X52/X60/X70 etc.

L245/L290/L320/L360/L415/L485 etc.

|

| PSL-2 |

| Coating |

FBE/3LPE According to AWWA C213,DIN 30670 or ISO 10080 etc (See the Chart Below) |

| Outside Diameter Ranges |

3/4’’~48’’ Or DN20~DN1200 Or 26.7mm~1219mm |

| Wall Thickness Ranges |

SCH10~SCH160 Or STD,XS,XXS Or 1.73mm~59.54mm |

| Length

(negotiable)

|

For 20Ft Container |

4.8m-5.8m |

| For 40Ft Container |

4.8m-12m |

| Most common choice |

6m, 12m |

| Type |

Welded |

All normal sizes |

| Seamless |

More about Coated Steel Pipe

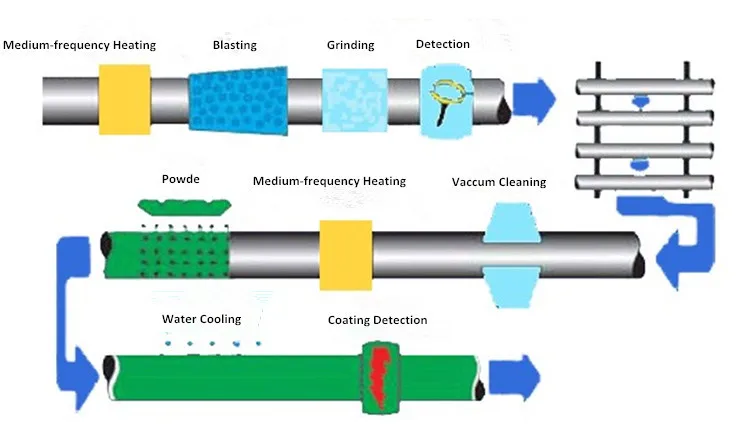

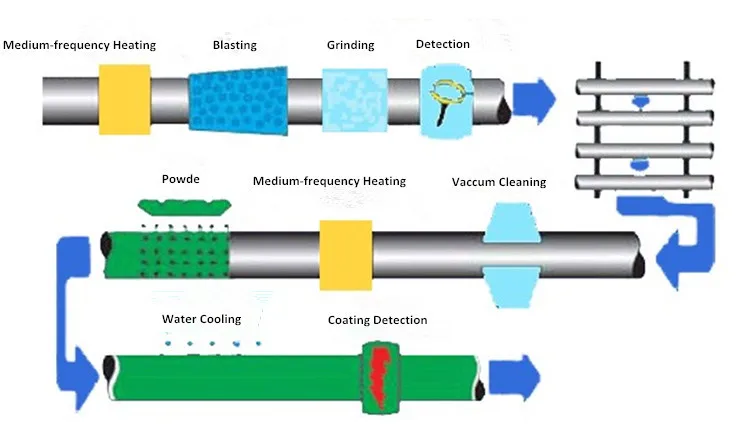

—FBE Coating Pipe( Fusion Bonded Epoxy Coating Pipe)

| Coating Type |

Coating Level |

The Min.Thickness (um) |

| FBE(Single-Layer External Fusion Bonded Epoxy Powder Coating) |

Normal |

300 |

| Reinforce |

400 |

| 2FBE(Two-Layer External Fusion Bonded Epoxy Powder Coating) |

Normal |

Bottom |

250 |

| Surface |

370 |

| Reinforce |

Bottom |

300 |

| Surface |

500 |

| Internal FBE Coating |

Normal |

250 |

| Reinforce |

350 |

| Liquid Epoxy Internal Coating |

Normal |

200 |

| Reinforce |

300 |

| Extra-reinforce |

450 |

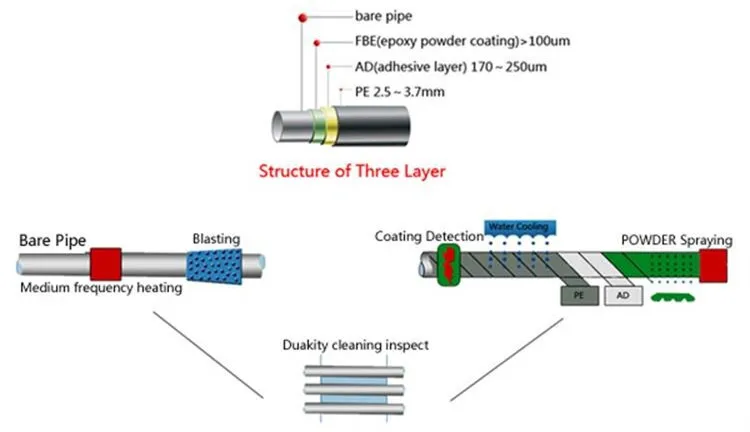

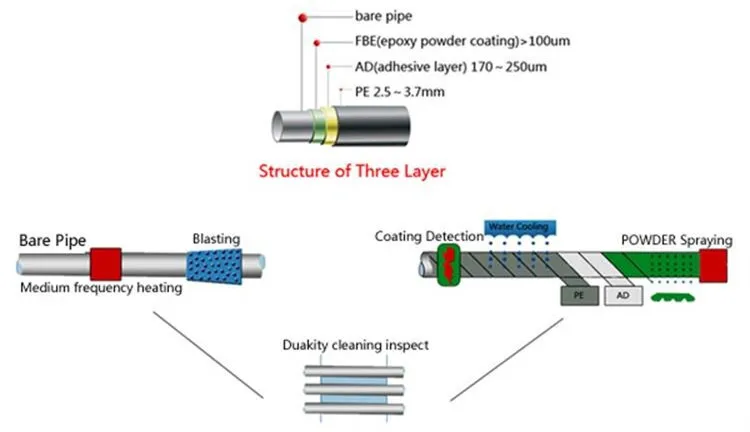

—3LPE Coating Pipe(3PE Coating Pipe)

| Coating Type |

Coating Layer |

Nominal Diameter(DN) |

Epoxy Thickness |

Adhesive

Thickness

|

PE Min.Thickness (mm) |

| Normal |

Reinforce |

3PE

Three layers polyethylene |

inside layer: expoxy

mid layer: adhesive

outside layer: polyethylene |

DN≤100 |

≥120um |

≥170um |

1.8 |

2.5 |

| 100 |

2.0 |

2.7 |

| 250 |

2.2 |

2.9 |

| 500≤DN<800 |

2.5 |

3.2 |

| DN≥800 |

3.0 |

3.7 |

2PE

Two layers polyethylene |

inside layer: adhesive

outside layer: polyethylene

|

DN≤100 |

/ |

≥170um |

1.8 |

2.5 |

| 100 |

2.0 |

2.7 |

| 250 |

2.2 |

2.9 |

| 500≤DN<800 |

2.5 |

3.2 |

| DN≥800 |

3.0 |

3.7 |

Previous: High strengh frp pipe grp pipe fiberglass pipe

Next: api 5l 3PE x70 psl2 steel line pipe ,3lpe coating pipe,iso api 5l steel line pipe with PE coating