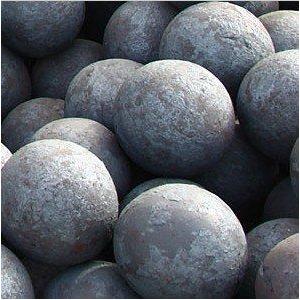

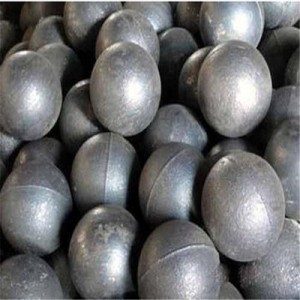

forged steel grinding balls mill parts

The field of applications for the Cast Chrome Alloy Grinding Steel Balls, in short Cast Steel Balls, can be found in Cement

Plants, Mines, Power stations, Chemical Industries, Grinding Mill, Ball mill and Coal mill.

Plants, Mines, Power stations, Chemical Industries, Grinding Mill, Ball mill and Coal mill.

We have available 4 maintypes of these balls: Low chrome, medium chrome, high chrome and higher chrome. Sizes are in the range 10mm – 150mm.

Features:

1. forged steel grinding ball has high hardness: surface hardness to 58-65HRC, volume hardness of 57-64HRC

2. impact toughness high: impact toughness more than 12J / cm2.

3. broken rate is low: the actual broken rate is not higher than 0.5%.

4. loss of forged grinding ball round rate is low.

5. dropping test in 8m high tester for more than 20,000 times.

1. forged steel grinding ball has high hardness: surface hardness to 58-65HRC, volume hardness of 57-64HRC

2. impact toughness high: impact toughness more than 12J / cm2.

3. broken rate is low: the actual broken rate is not higher than 0.5%.

4. loss of forged grinding ball round rate is low.

5. dropping test in 8m high tester for more than 20,000 times.

Specification

Main specifications for Cast Chrome Alloy Grinding Steel Balls:

|

Parameters

|

Low Chrome

|

Medium Chrome

|

High Chrome

|

Higher Chrome

|

|

Cr %

|

0.8 – 3.5

|

4 – 9

|

10 – 18

|

22 – 25

|

|

C %

|

2.2 – 3.5

|

2 – 3.3

|

1.6 – 3.3

|

2.0 – 3.3

|

|

Si %

|

1.2 max

|

1.2 max

|

1.0 max

|

1.0 max

|

|

Mn %

|

1.5 max

|

1.8 max

|

2.5 max

|

2.5 max

|

|

Mo %

|

1.0 max

|

1.5 max

|

1.0 max

|

2.0 max

|

|

Cu %

|

0.5 max

|

1.0 max

|

1.5 max

|

1.5 max

|

|

P %

|

0.15 max

|

0.15 max

|

0.10 max

|

0.10 max

|

|

S %

|

0.15 max

|

0.15 max

|

0.10 max

|

0.10 max

|

|

Metallographic structure

|

Carbide + Pearlite

|

Carbide + Pearlite

|

Carbide + Martensite

|

Carbide + Martensite

|

|

Hardness (HRC)

|

45 or above

|

50 or above

|

58 or above

|

60 or above

|

|

Times of falling ball

|

8000 or above

|

12000 or above

|

15000 or above

|

22000 or above

|

Available ball diameters:

|

Nominal Diameter in mm

|

Weight in kg per ball in average

|

Number of Balls per ton in average

|

|

10

|

0.135

|

74073

|

|

12

|

0.0181

|

55248

|

|

15

|

0.0242

|

41322

|

|

20

|

0.0322

|

31056

|

|

25

|

0.063

|

15873

|

|

30

|

0.11

|

9091

|

|

40

|

0.257

|

3891

|

|

50

|

0.5

|

2000

|

|

60

|

0.867

|

1153

|

|

70

|

1.37

|

729

|

|

80

|

2.05

|

487

|

|

90

|

2.90

|

345

|

|

100

|

4.00

|

250

|

|

110

|

5.30

|

188

|

|

120

|

6.80

|

147

|

|

125

|

7.75

|

129

|

|

130

|

8.74

|

114

|