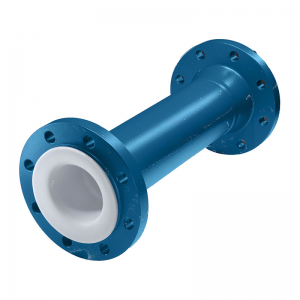

We supply pipe spools of sizes up to DN-300 and a maximum length of 3000mm. These spools are seamless pipe sections to which the plastic liner is thermally locked from inside & flared at ends conforming to ASTM A 106 sch-40 conforming to ASTM F 1545 suitably provided with vent holes to prevent liner failure against different temperature and pressure and permeation conditions. These lined spool pipes can be supplied with lose or fixed flange design to any drilling specification upto DN – 300 sizes. As a solution to customer’s applications Jacketed Lined Pipes can also be made available.

HOUSING MATERIAL

Pipe : 1. Seamless Carbon Steel ASTM A 106 Gr.B.Sch-40

2. ASTM A 312 TP 304,Sch-40

Flanges : 1. Made from IS 2062 Plates/ASTM A 105

2. ASTM A 351 Gr.CF 8

Liner : PTFE in accordance with ASTM D 1457

OPTIONS

Pipe : Jacketed Spool Pipe can be supplied on request

Flanges : DIN PN 10 / 16, BS 10, ASME 300, Mixed

Extras : Earthing Studs / Lugs, Vent Extensions

Material : Stainless Steel

Liner : HDPE / PP

NOTE

Special heavy duty PTFE Liners available for full vacuum. Details can be provided on request. Other Flange Drilling like DIN 2632 / 2633, BS 10 Table D, E or F are also available on request. Tolerance : ± 3.5 mm ( 0 to 1mtr.) and ± 5.0mm (1 to 3 mtr.) Clear ID for HDPE/PP Lined Pipes (DN/ID ) : 25/18, 40/32, 50/42,65/57, 80/67.

TEST & INSPECTION DATA

Resins are conforming to the requirements of ASTM F 1545-97(2003)

Hydraulic Test : 20 Kg / Cm2 After Lining

Spark Test : 15 KV D.C After Lining

Vent Extensions

When the lined piping system will be lagged, please specify that the spools and fittings should be supplied with vent extensions, these 75mm long extension protrude through the lagging allowing the correct venting of the lined equipment.

Venting

All lined piping systems must have vent holes drilled through the steel body. This is for 2 reasons, firstly to vent any gasses that may permeate through the liner witch can be detrimental to liner life to the atmosphere rather than allow them to build up behind the liner trapped within the steel pipe. Pipe spools less than 500mm have 2 off vent holes located centrally, longer spools have 4 vent holes 1 pair located at each end.