Detail images:

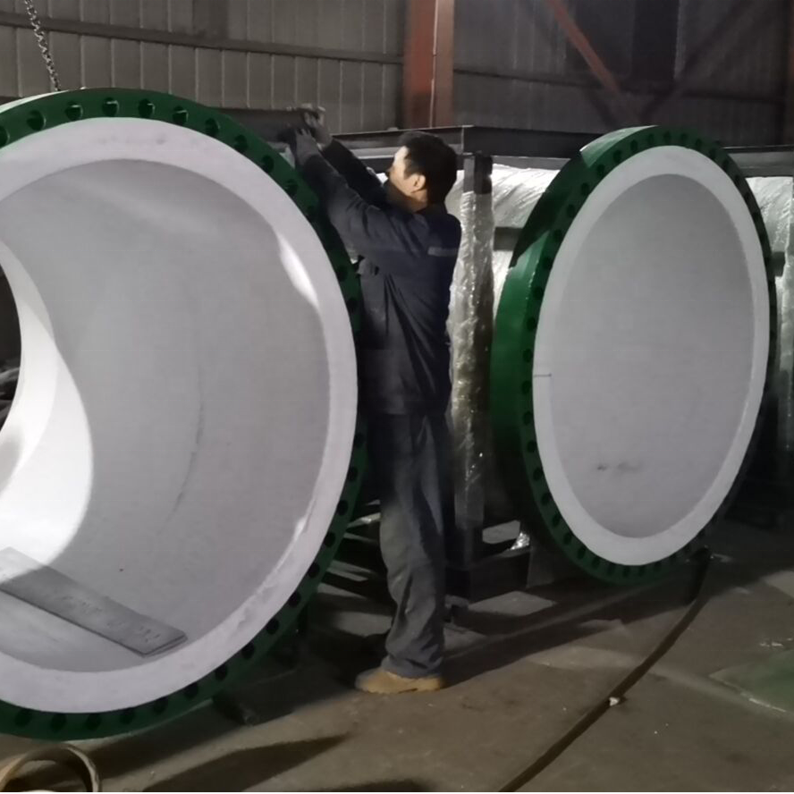

PTFE lined Equal Tee

Overview:

PTFE powder with high performance is used to push (squeeze) into the pipe, the surface is chemically treated, and then it is lined into seamless steel tube (the outer diameter of the liner is slightly larger than the inner diameter of the steel tube 1.5-2mm) to form a seamless liner.To relieve the stress, it is placed in a furnace and heated to 180 degrees for constant temperature treatment, so that it is suitable for use in temperatures below 180 degrees.At the same time, the axial tensile strength of push (squeeze) pressure pipe is obviously better than that of winding pipe, which can be used in micro-negative pressure pipeline.

Industries:

Acid Transfers, Caustic & Chlor- Alkali, Chemicals, Pharmaceuticals, Water Treatment

Feature & Benefits:

1.The piping and fittings were tested hydraulically at 1.5 times the design pressure.

2.Where PTFE lining is involved, 100% integrity test is conducted after hydrostatic test, and the leakage point test method is electric spark test.

3.lining material: PTFE,PFA,FEP,PVDF,PO,PP,PE

Medium: strong acid, strong alkali, organic solvent, strong oxidant, toxic, volatile, flammable chemical medium

Connection: flanged

Lining Specifications:

Lining Material

We offer lining materials like PTFE,PFA,FEP,PVDF,PO,PP,PE

Temperature:

PTFE Max : 260°C ,FEP Max : 204°C ,

PFA Max : 260°C ,

PVDF Max : 140°C ,

PO Max : 80°C

PE Max : 70°C ,

PP Max : 120°C

Lining Thickness

Min. 3.0mm

Spark Test

Body liners & all wet parts are tested for spark at 15,000 Volts

Overview:

PTFE powder with high performance is used to push (squeeze) into the pipe, the surface is chemically treated, and then it is lined into seamless steel tube (the outer diameter of the liner is slightly larger than the inner diameter of the steel tube 1.5-2mm) to form a seamless liner.To relieve the stress, it is placed in a furnace and heated to 180 degrees for constant temperature treatment, so that it is suitable for use in temperatures below 180 degrees.At the same time, the axial tensile strength of push (squeeze) pressure pipe is obviously better than that of winding pipe, which can be used in micro-negative pressure pipeline.

Industries:

Acid Transfers, Caustic & Chlor- Alkali, Chemicals, Pharmaceuticals, Water Treatment

Feature & Benefits:

1.The piping and fittings were tested hydraulically at 1.5 times the design pressure.

2.Where PTFE lining is involved, 100% integrity test is conducted after hydrostatic test, and the leakage point test method is electric spark test.

3.lining material: PTFE,PFA,FEP,PVDF,PO,PP,PE

Medium: strong acid, strong alkali, organic solvent, strong oxidant, toxic, volatile, flammable chemical medium

Connection: flanged

Lining Specifications:

Lining Material

We offer lining materials like PTFE,PFA,FEP,PVDF,PO,PP,PE

Temperature:

PTFE Max : 260°C ,FEP Max : 204°C ,

PFA Max : 260°C ,

PVDF Max : 140°C ,

PO Max : 80°C

PE Max : 70°C ,

PP Max : 120°C

Lining Thickness

Min. 3.0mm

Spark Test

Body liners & all wet parts are tested for spark at 15,000 Volts